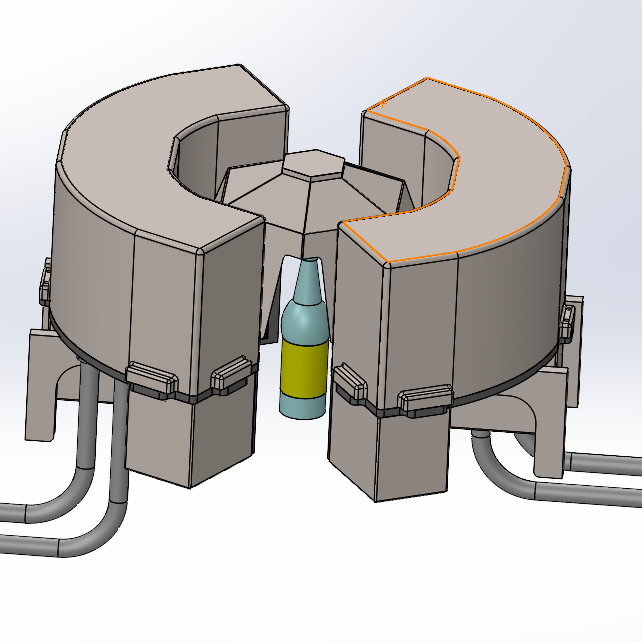

Bottle Ainspection

AUTOMATION, ACCESSORIES AND COMPONENTS

+ 2

Information

Total Bottle AInspection is born to inspect every feature of your products, thus safeguarding 100% of your production.

The system is designed to integrate perfectly within your line, thanks to small footprints intended not to impact the existing layout.

Total Bottle AInspection is a ready-to-use, modular all-in-one solution, allowing the system to evolve to meet future challenges.

Looking behind the limits:

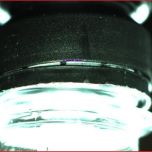

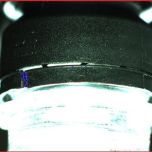

Small cracks, scratches and imperfections are the nightmare of the perfect container, especially on transparent Glass & Plastic.

Cap inspection

A total coverage from any defect, starting from the pre-capping:

Anti-mix-up, verification of the inner seal presence, and its correct direction of application.

It is also possible to inspect the closure’s surface after their application, in search of micro-depressions generated during the process, surface defects, or to verify the centering and integrity of the codes written on the top of the closures.

Neck label inspection

The solution consists of n. 6 cameras with as many dedicated mirrors, suitably configured to obtain the correct and optimal optical path.

The system uses artificial intelligence algorithms specifically trained in identifying and analyzing - on transparent and opaque labels - the following process defects:

Bubbles

Wrinkes

Folds

Absolute vertical misalignments

Relative vertical misalignments

Absolute horizontal misalignments

Relative horizontal misalignments

Overlap

Non-correspondence between label and product

Missing label

Neck label inspection

The solution consists of n. 6 cameras with as many dedicated mirrors, suitably configured to obtain the correct and optimal optical path.

The system uses artificial intelligence algorithms specifically trained in identifying and analyzing - on transparent and opaque labels - the following process defects:

Bubbles

Wrinkes

Folds

Absolute vertical misalignments

Relative vertical misalignments

Absolute horizontal misalignments

Relative horizontal misalignment

In evidenza

AUTOMATION